Understanding the Process

One of the oldest known metal-forming techniques, Dameron Alloy Foundries continues to push for improvements in our process by utilizing the newest technology available in our industry.

Casting Process

1. Wax Injection

Wax is injected into aluminum die/tooling to produce a wax pattern of the desired part. This process must be repeated to produce as many waxes as required on the customer order. The design and condition of the die/tooling is critical due to the fact that any imperfections on the wax pattern will be evident in the metal cast part if not repaired in wax stage.

2. Soluble Core Injection

Some investment casting designs require a detailed interior core. In the event the geometry requires such detail, the soluble wax core process can be utilized. A separate die/ tooling will be required to produce the soluble core wax pattern.

3. Wax/ Soluble Injection

The soluble core is placed inside the wax pattern tool. The pattern wax is injected around the soluble core to produce the desired interior and exterior geometry.

4. Wax/ Soluble Assembled

The completed wax pattern will then be submerged in an acid/water solution to leach/dissolve the soluble wax core, leaving only the wax pattern in tact. The final wax will then represent all of the desired and complex interior geometry.

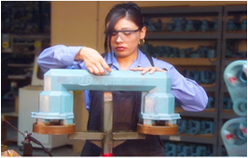

5. Wax Assembly

The wax patterns are inspected 100% for any imperfections and cleaned/repaired accordingly. The wax patterns must be perfect as any imperfection will show up in the metal casting if not eliminated in the wax stage. Wax patterns are then assembled on to specific engineered “Tree” designs to produce a complete wax mold. The “Tree” design is critical as this is how the metal will ultimately be distributed into the mold and feed the casting. DAF utilizes state of the art solidification modeling software to assist in the design of our “Tree” feeding system.

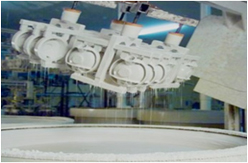

6. Shell/Dip Room

Trees are then loaded on to the dip room conveyor and queued to begin the shell/dip process.

7. Shell/ Dip

The trees are first dipped into a slurry, and then a specific refractory stucco sand. Specific dry times for the various dip coats are assigned to each individual part based on the complexity of the design/geometry.

8. Drying Process

The dipping process will repeat an average of 7-8 times over several days to form a sufficient ceramic “Shell” around the wax mold.

9. Dewax Autoclave/Flash Fire

After the part has been dipped and the shell is dried completely, the wax inside the shell is removed using a flash fire or a steam operated autoclave.

10. Metal Prep. and Mold Preheat

The required alloy is then prepared and melted to its specific pouring temperature while simultaneously the ceramic shells are heated up to a specific desired temperature.

11. Pouring

Once the metal and shells have reached the required temperature, the shells are removed from the oven and the metal is poured into the hot mold.

12. Shell Removal

After casting, the metal filled shells/molds cool off to room temperature. The ceramic material is then removed from the cast mold by either knockout hammer or stainless steel shot blast. Any remaining ceramic may be manually sandblasted.

13. Cut-off and Grind

Once all of the ceramic has been removed from the metal molds, the castings are cut-off the tree using an abrasive wheel. The next step of the process is gate removal. Abrasive belts and or hand finishing tools are used to grind remaining gate flush to the surface of the casting.

14. Rough Inspection and Rework

A rough visual inspection is performed on 100 percent of all castings to identify any unacceptable defects. Subsequent re-work such as welding, de-burr or blending is then performed in all castings.

15. Straightening and Dimensional

Once all of the ceramic has been removed from the metal molds, the castings are cut-off the tree using an abrasive wheel. The next step of the process is gate removal. Abrasive belts and or hand finishing tools are used to grind remaining gate flush to the surface of the casting.

16. Post Cast Processes

Heat Treat, Non Destructive Testing, Passivation, E-Polish, Nickle/Chrome Plating, Anodize, Painting and Additional processes available per customer request

17. CNC Machining

CNC Machining capability is available if finished product is desired by our customers. Our Mexico facility has over 20 CNC machines occupying approximately 18,000 sq. ft. With a wide selection of lathes and 4 axis mills, we can accommodate a variety of part sizes and complex requirements. We have a network of sub contracted machining sources available as well.

18. Final Inspection

Prior to shipping all parts receive a visual inspection, as well as dimensional inspection per customer requirements.

19. Inventory to Shipping

Customer parts are counted, marked per customer’s instructions, documentation is finalized, and then the shipment is packed and sent to one of the 53 countries in which we do business.

Dameron also offers DMI - Dameron Managed Inventory.